Triton Injector

Jump to navigation

Jump to search

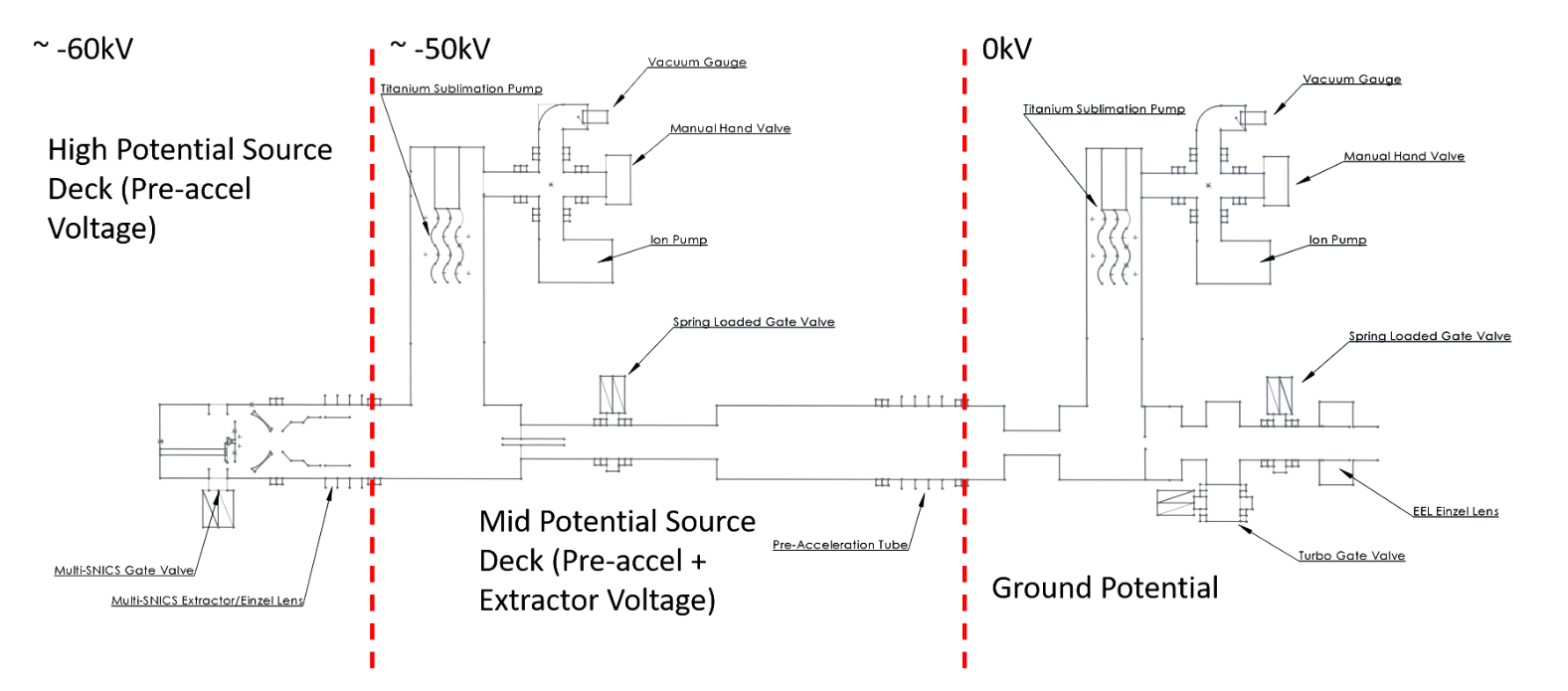

The Triton Injector has components located at three different potentials with different systems:

Ground potential

- Vacuum pumps: Titanium-Sublimation Pump (TSP) 2, Ion-getter pump (IGP)2, Turbo Pump, Roughing pump

- Vacuum instrumentation: Ion-gauge, 2 TC, creating "Good vacuum 2" condition

- Preaccelerator HV(-55 kV) supply

- Fumehood Activity Monitor

- Source Cooling

Interlock controller (monitoring Vacuum status from GND, -55 kV, monitoring cooling status, fumehood activity, AC power status) (providing shutdown signal for source Gate-valve, ion source power, Preaccelerator HV.)

-55 kV potential

- Vacuum pumps: TSP 1, IGP 1

- Vacuum instrumentation: Ion-gauge, TC, creating "Good vacuum 1" condition

- Gate-valve controller, interlocked with GND-level controller

-65 kV potential

- Ionizer Power supply

- Extractor V Supply

- Einzel Lens Supply

- Cathode V Supply

- Immersion-Lens V Supply

- CS Boiler Supply (Variac)

All power is interlocked with GND-level Interlock controller: Ionizer Power Supply has Battery-backup and "10 second" interlock turn-down. All other Power-supplies are turned down fast by interlock.