Tandem Accelerator

Tandem Beamline SF6-Gas Security Ball Valves

Each beam line exiting the Tandem has a large diameter, pneumatically actuated Worcester Controls ball valve that will automatically close under normal operating conditions if a pressure rise on the order of in. of Hg is detected on the Tandem side of the valve. Because the Tandem is filled with SF6 at 85 psi and the accelerator tubes and beamline are under vacuum a failure of an O-ring seal, accelerator tube metal to glass bond or any major compromise of vacuum integrity within the machine could have catastrophic results. The intention of the valves are two fold. One is to contain the gas to prevent its loss, a $70,000 investment. The other is to prevent damage to the equipment on the beam line that is designed to withstand the implosive forces of vacuum and not the explosive 85 psi tank pressure.

An Edwards High Vacuum Ltd. pressure switch is located on the L.E. end of the Tandem beam line to sense the fault condition along with a 30 in. Hg to 60 psi compound gauge to monitor the tube vacuum/pressure in the range where penning gauges and thermocouples are not usable. The control panel is in the vault L.E. electronics rack below the beamline, and the key switch for disabling control of the ball valves is kept in the red case underneath the Control Room console. When the vault control panel is in the unprotected key switch position the ball valves can be opened and closed at will. In the protect position the ball valves can only be opened when the beamline pressure switch is closed. An LED on the control panel, labeled sensor contact, will illuminate when the switch is closed.

The Gas Security Ball valve controller is integrated with the Tandem Pelletron interlock circuit. A closure of the ball valve either manually or due to a failure of the vacuum integrity is sensed by the Ball valve controller and results in the Pelletron charging supplies being interrupted via the interlock panel.

Because they are pneumatically controlled, a loss in compressed air service will result in the valves closing. There will be no electric circuit indication such as the sensor contact LED being off or the Pelletron H.V. supplies being tripped off. If beam transmission through the machine is nil, investigating the ball valves themselves will allow ascertaining the valves’ state. On top of the pneumatic actuators are square posts that turn with the ball valve, the valves are open if the small silver stud on one of the flats is facing West.

Tandem Beamline Vacuum Protection System

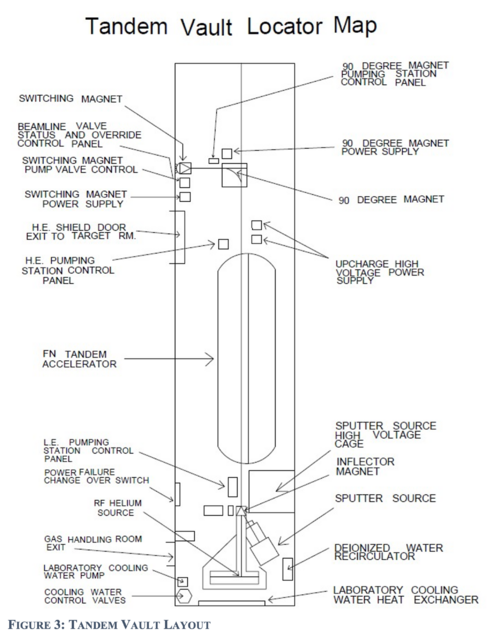

The logic and status chassis for the Tandem Vault beam lines is above the switching magnet power supply, North of the H.E. vault shield door. There is a status panel also in the Control Room above the beamline devices panel (figure 4). The L.E., H.E., Sputter Source and Polarized Source vacuum indications are displayed in the Control Room also.

Each Tandem beamline fast valve has a dedicated control box and penning gauge except for the 90◦ magnet which has a penning gauge but no fast valve to control. Each controller has a “good vacuum” output signal that is “anded” together in the logic chassis with the other controllers. If any of the five penning gauge controllers detect a vacuum incident, all four of the fast valves will close and the Tandem Pelletron charging H.V. supplies will be disabled.

The Tank Gas Security Ball Valve Controller is also “anded” with the beamline penning gauge controllers in the logic chassis and an LED indication for the ball valves status is provided. If either the L.E. or H.E. Gas Security ball valve is closed, the Pelletron H.V. charging supplies are disabled. If the ball valves have closed on their own something could be severely wrong and a staff member familiar with this system should be consulted before they are reopened. More information about the Gas Security ball valves can be found in Sec. 18.

The source penning gauge is not included in the “anded” logic to close the beamline valves. The source penning gauge will close the source exit valve and turn off the preaccelerator H.V. supply if the ion source vacuum sufficiently degrades. The valve control boxes for the two sources are different, so, arbitrary interchanging of the boxes cannot be done.

The fast valve control box/penning gauge controllers themselves do have many common features. The valve control boxes can be used to open and close a valve at will in the unprotected mode (no vacuum consideration). In the protected mode, the valve can only be opened if the vacuum at the associated gauge head is better than the chosen set point, approximately 5 x 10−6. A controller that has sensed a vacuum excursion will have a flashing LED; to rearm the protection circuit and open the valve(s) that has tripped close, depress the push button reset switch on the front panel of that controller, the LED should stop flashing. Be cautious with the beamline valves: if all the controllers sense a good vacuum and all valve switches are in the open position, all four fast valves will open simultaneously. If this is not desired, place the valve control box switches to close, reset the tripped penning gauge controller, and then open the valves individually. If a penning gauge controller is out of service or it is desirable to prevent a controller from closing the beam line valves, it can be overridden at the logic panel by placing the switch indicated for that controller in the override position. The Ball valves should only be overridden after a staff member familiar with this system has been consulted.

Tandem Pelletron Interlock Panel

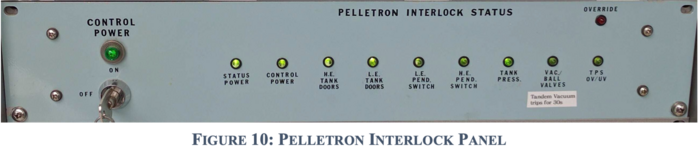

To prevent dangerous operation of or damage to the accelerator an interlock circuit is employed. The status of the various interlock switches is displayed at the interlock panel. The switches and their status are in a serial configuration therefore should one interlock not be closed all others “down stream” will also indicate an open situation and the LEDs will be extinguished. The panel layout is natural in that all the LEDs to the right of the offending switch will be out; once that interlock is satisfied its LED will illuminate and the rest to its right should also shine if the switches are closed. The interlock circuit, depending upon which switch opens up, will either turn off the charging supplies or both the charging supplies and the chain drive motors. All the interlocks up to and including the tank pressure switch will disable both the chain drives and power supplies, the remaining only affect the charging supplies.

There are nine LEDs on the Tandem Pelletron Interlock Panel, see figure 10. A brief description of each interlock or LED indication in the order that they are appear on the panel follows.

Status Power: This lamp will be lit if the power switch key is turned to on and the 12V dc supply used for the series circuit is present.

Control Power: This lamp indicates AC power is present within the chassis when the switch key is turned to on.

HE Tank Door: A push button switch is mounted on the Tandem High Energy Tank Door to sense when the door is fully rotated closed.

LE Tank Door: A push button switch is mounted on the Tandem Low Energy Tank Door to sense when the door is fully rotated closed.

LE Pendulum: A push button switch is mounted to the LE drive sheave assembly to sense excessive Pelletron chain stretch or failure.

HE Pendulum: A push button switch is mounted to the HE drive sheave assemblyto sense excessive Pelletron chain stretch or failure.

Tank Pressure: A pressure switch is mounted to the Tandem pressure vessel to ensure a minimum pressure of 35 psi is established before the Pelletron chain is started.

Vac Ball Valves: This interlock is closed when the Tandem Beam Line Valve Protection System detects no tripped penning gauge controller or beamline SF6 protection ball valve closure. A separate status panel is present in the Control Room for this beamline protection system and an override/status panel is located in the Tandem Vault to the North of the HE door. A more detailed description of that circuit can be located through the Table of Contents.

TPS OV/UV: The Terminal Potential Stabilizer supplies a relay that relaxes whenever the terminal voltage varies beyond a set percent of the value displayed at the terminal voltage reference potentiometer. This TPS feature must be enabled to trip the interlock panel for an out of range voltage excursion.

Should a condition arise where disabling the Tandem Pelletron Interlock Panel is desired, such as a tank opening, an override switch is located in the back of the panel chassis. It is accessible from behind the electronics racks.

Terminal Potential Stabilizer

The Terminal Potential Stabilizer (TPS) consists of five main components: Controller Unit, Generating Voltmeter (GVM), Analyzing Slits, Capacitive Pick-Off Plates (CPO) and the Corona Probe.

The Controller as is suggested, controls the terminal voltage by comparing signals from the GVM, slits and the CPO to produce a correction signal that modulates the current flowing to the terminal from the corona probe.

The GVM is mounted on the tank wall of the Tandem opposite the terminal. A four bladed rotor spins at 3450 rpm over a surface divided into eight segments each the size of one blade. As the rotor spins it uncovers some segments and exposes them to the terminal voltage which results the segment charging to a voltage proportional to the terminal voltage. When the segment is again shielded by the rotor, charge will drain away. The signal produced by the GVM is conditioned locally by an amplifier and routed to the controller.

The analyzing slits are in the typical configuration, downstream of the 90◦ analyzing magnet, parallel to the pole face plane and opposite each other on the exiting beamline. They are adjustable with micrometer style knobs for each and are electrically isolated. Beam being bent around the 90◦ magnet impinges upon the slits creating a signal proportional to the beam it senses. The signals from the slits are conditioned locally by an amplifier and routed to the controller.

There are two CPO plates in the Tandem that are mounted on the tank wall opposite the terminal. These plates are electrically isolated and sense fluctuations of terminal voltage at frequencies above those detectable by either the slits or the GVM. Two plates are used to cancel out physical movement of the column that would be detected as a voltage fluctuation by a single plate as the separation between the terminal and plate changes. The signal from the CPO plates is conditioned locally by an amplifier and routed to the controller.

The corona probe is also mounted on the tank wall opposite the terminal. The probe is mounted on a shaft that can be driven to different distances to the terminal depending on the terminal operating voltage. The end of the probe consists of a shell with 12 needle points extending slightly beyond the polished shell surface. The voltage on the needle points determines the flow of electrons to the positively charged terminal. Modulating this flow of electrons is done by the Controller based on the information provided by the GVM, slits and the CPO.

The typical operation of the system is described to assist the operator in understanding how the system maintains terminal stability. The description is not intended to be used for bringing up the terminal voltage as it excludes the Charging Controllers and positioning of the corona probe. Feedback or modulation of the probe current will take place only when the TPS Control Gain is turned up. The Controller has three possible modes of operation namely GVM, Slit or Auto. The Auto mode allows the TPS to switch into one of the other two modes depending whether the terminal voltage is approximately 50 KV off of the controller Terminal Voltage Reference Potentiometer setting and/or beam current above 10 nanoamperes is sensed by the analyzing slits. Typically the Controller is in the Auto mode.

With less than 10 nanoamperes of beam on the analyzing slits, the Tandem will be in GVM mode. The correction signal in this mode is derived by comparing the front panel Terminal Voltage Reference Potentiometer setting to the GVM measurement of actual terminal voltage. The CPO signal is added to this to produce the error signal that ultimately modulates the corona probe voltage. The operating voltage of the probe needles is proportional the Grid Bias indicated on the Controller chassis. In this mode the terminal voltage will track the Reference Potentiometer setting and allows one to scan the terminal voltage until beam strikes the analyzing slits.

With beam on the slits and the GVM and Terminal Voltage Reference Potentiometer in relative agreement the TPS Controller will switch to Slit mode. The controller compares the current striking one slit to the other to create an error signal that attempts to keep the measured current balanced. The slit on the inside of the analyzing magnet bend is the Low Energy (LE) slit and the one on the outside is the High Energy (HE) slit. If an excess of beam is detected by the LE slit an error signal is produced by the TPS that will reduce the probe electron current flowing to the terminal causing the terminal voltage to rise which will bring more beam current to bear on the HE slit until a balanced situation is again reached. Like the GVM mode, the CPO signal is added to modulate the probe current. In this control mode adjusting the Terminal Voltage Reference Potentiometer has no effect until the disagreement with the GVM causes the TPS to revert to GVM mode. When the TPS is in Slit mode the Reference Potentiometer should be adjusted to agree with the GVM indication.

Operating Instructions for the Tandem Pelletron

To Turn the Tandem Pelletron On

- Set the TERMINAL POTENTIAL STABILIZER CONTROL MODE to AUTO and turn the CONTROL GAIN and CPO GAIN to zero.

- Turn on the LOW ENERGY CHARGING CONTROLLER AND THE HIGH ENERGY CHARGING CONTROLLER by turning their key switches CW to the ON position. To start the charging chains lift the momentary CHAIN switch to

- the ON position for each CONTROLLER. After approximately ten seconds the lamp below the switch will illuminate indicating the chain is up to speed.

- Set the corona probe BIAS CURRENT to 35 microamps on the TPS

- Set the corona probe to the approximate position indicated in the table for the desired terminal potential.

- Set the GVM REFERENCE VOLTAGE knob to the correct voltage (e.g. 8 MV would be “0800”).

- Ensure the TERMINAL CHARGE POTENTIOMETER on the LOW ENERGY CHARGING CONTROLLER is turned down to zero, CCW.

- Turn both POWER SUPPLY switches to ON on the CHARGING CONTROLLERS. Their indicator lamps should glow.

- While watching the corona probe GRID voltage, carefully increase the charge carried by the chains by turning the TERMINAL CHARGE POTENTIOMETER CW. Turn the TERMINAL CHARGE POTENTIOMETER until the GVM/TV

- Balance indicates approximately zero or the GRID voltage has reached -9V. If any time the GRID voltage reading goes beyond -1OV, run the corona probe out to reduce it. Fine tune the corona probe position and the up-charge so that the GRID voltage reads approximately -9V when the desired terminal voltage is reached.

- Enable the OVER/UNDER VOLTAGE PROTECTION and set both the CONTROL GAIN and CPO GAIN to 5.

- Readjust the corona probe if necessary to attain -9V; do not exceed this voltage on the GRID.

- Set the 90◦ magnet to the appropriate field and put beam through the Tandem. If the TPS does not switch to the SLIT CONTROL MODE and lockup on a beam the GVM REFERENCE VOLTAGE knob can be adjusted slightly to scan for the

- beam; only a slight adjustment should be necessary.

- With beam on the slits, and the TPS in SLIT CONTROL MODE adjust the TERMINAL CHARGE POTENTIOMETER so that the Slit Balance meter reads zero, and retrim the corona probe position, if necessary, to get -9V on the GRID.

- Adjust the GVM REFERENCE VOLTAGE knob so that the GVM/TV Balance meter indicates approximately zero.

If there is a spark

The OVER/UNDER VOLTAGE PROTECTION interlock on the TERMINAL POTENTIAL STABILIZER panel will be tripped and the red LED should be lit. The CHARGE CONTROLLER POWER SUPPLIES are disabled by this protection circuit, however, the chains will continue to run.

- Turn the CONTROL GAIN and CPO GAIN to zero

- On the LOW ENERGY CHARGING CONTROLLER turn the TERMINAL CHARGE POTENTIOMETER back to zero.

- Reset the TPS OVER/UNDER VOLTAGE PROTECTION interlock by depressing the momentary switch.

- Turn up the TERMINAL CHARGE POTENTIOMETER until the previous terminal potential is reached; watch for signs of conditioning.

- Check that the GRID voltage reads approximately -9V .

- Set the CONTROL GAIN and CPO GAIN to 5.

- Put beam through the Tandem Pelletron and adjust the TERMINAL CHARGE POTENTIOMETER to center the Slit Balance meter.

- Enable the OVER/UNDER VOLTAGE PROTECTION circuit.

To TURN OFF the Tandem Pelletron

- Disable the “TPS OVER/UNDER VOLTAGE PROTECTION” and turn the “CONTROL GAIN” and “CPO GAIN” to zero.

- On the Charging Controller Turn the “TERMINAL CHARGE POTENTIOMETER” back to zero and turn off the CHARGING POWER SUPPLIES at the toggle switch. Depress the momentary switch for the chains to turn them off and then

- turn the panel key switch to off.

Power Failure Procedures

When the mains fail the emergency generator should start automatically. If the emergency lights come on, the generator is running correctly. The changeover breaker should switch automatically and restore power to all pump circuits. If this does not occur, the change over breaker, located on the West wall of the accelerator vault between the L.E. door and the sink, should be assisted with a 2-by-4. Note: In the emergency-power position, the central arm should be down.

When emergency power is available at the pumping stations a number of things should be checked

- Check that the recirculating pump, located just to the South of the L.E. door in the accelerator vault, is running. Restart if necessary. See Water Cooling System.

- Check that source pumping stations are operating normally. Restart pumps and reopen valves as necessary.

- Check the turbo pump at the H.E. end, it may have tripped and be coasting down. It should be restarted.

- Check Cryopump. If the supply was only interrupted for a few seconds the compressors will restart automatically, but the input and output pressures will remain the same for approximately one minute; then the unit will switch and normal pressures will be reestablished. When this occurs the coldhead will restart and the vibration of this motion will be felt at the cold head. If the power is off long enough for the pump to start to warn and outgas, it will have to be started again. See the section 4 for cryopump head regeneration.

- The pumps in the target room should be checked to ensure that they are running normally. Restart or close off as necessary.

- When mains voltage is restored the changeover breaker will wait a short time, to ensure that the supply will probably remain on, and then will automatically change over and the emergency generator will shutdown. If the breaker hangs up it can be assisted up with the 2-by-4. When the mains supply has been restored to the pumping stations the previous checks should be repeated. When all vacuums are normal the beamline valves should be checked and reopened as necessary. Make sure that the vacuum is good on both sides before opening any valve.