Ion Sources

General

WARNING - The ion sources of the accelerator laboratory will be at extremely high voltages during operation, up to 120000 V.

Touching this equipment while at high voltage potential causes life-threatening electrical shocks

All parts of the equipment at high Voltage are enclosed by grounded metal cages for the protection of laboratory users.

Three cages are present: 1) The cage surrounding the SNICS ion source body 2) the SNICS power supply cage 3) The cage surrounding the helium ion source and the new tritium ion source.

Under no circumstance is personnel allowed to reach into the cage or use tools to attempt manipulating equipment inside the cages. Danger to your LIFE !

Any components that require user adjustment during operation are controlled through permanently installed isolating plastic rods, which can be adjusted from outside the cage.

Only qualified personnel B. Schmidt, Dr. L.Baby or Dr. I. Wiedenhoever are allowed to secure the High-voltage ion source areas using the Lockout procedures described below.

Always follow the operating procedures described below.

Sputter Source

The Sputter Source is used for most beams at the FSU accelerator. It is also identified by its brand name "SNICS".

Theory of Operation

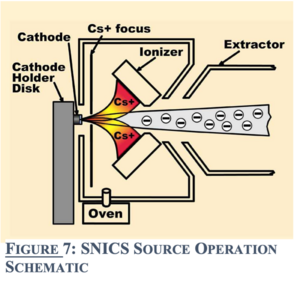

The Source of Negative Ions by Cesium Sputtering (SNICS) produces a negative ion beam. A reservoir of cesium metal is heated so that cesium vapor is formed. This cesium vapor comes from the cesium oven into an enclosed area between the cooled cathode and the heated ionizing surface. Some cesium condenses onto the cool surface of the cathode and some of the cesium is ionized by the hot surface. The positively charged ionized cesium accelerates towards the cathode, sputtering material from the cathode at impact. Some materials will preferentially sputter neutral or positive particles which pick up electrons as they pass through the condensed cesium layer on the surface of the cathode, producing the negatively charged beam.

Ion source operation states

The ion source and pre-accelerator can be in put into different states, depending on the phases of operation. The following procedures will make reference to transitions from one state to another. A) "Secured, Cold" state: All power sources are removed and locked-out. B) "Cold Idle" state: All power sources are turned off, but can be re-applied, the source and power supply cages stay closed. C) "Warm Idle" state: The power sources to the source remain on, but the "ionizer current" is turned down to preserve the source material fur further use. D) "Beam" state: producing ion beam to be injected into the tandem accelerator.

The source needs to be in the "Secured, Cold" state before any access to the ion source cage or the power supply cage is made.

Only qualified personnel Brian Schmidt, Dr. Lagy Baby and Dr. I. Wiedenhoever place the ion source into "Secured, Cold" state or to return it to beam operation from this state.

Temporary Turn Down: Bringing the source from "Operation" to "Warm Idle" state

Qualified Personnel: All trained accelerator operators

When a break or interruption in the experiment occurs and the negative ion source will not be required for four or more hours, it is desirable to turn down the source to prolong its operational life time.

- In the control room, turn the pre-accelerator high voltage supply to zero Volts.

- In the Tandem vault, close the source exit valve and switch the pre-accelerator high-Voltage supply off.

- Reduce the Cesium Boiler Heater to 35 on the variac scale by turning the control rod located at the high voltage cage.

- Reduce the ionizer heater current by turning the control rod attached to the ionizer power supply located at the SNICS power supply cage. Reduce the current in four-Ampere steps separated by two minute intervals to fifteen Amperes.

- Note in the Tandem Log Book, located in the Control Room, the time the source was turned down to the "Warm Idle" mode.

Bringing the source up from "Warm Idle" to "Beam" state

Qualified Personnel: All trained accelerator operators

- Insert the LE Faraday cup and select the LE cup current on the beam integrator.

- In the Tandem Vault, open the source exit valve after verifying the source vacuum status.

- Verify that the source cage is closed and that the source is ready to start beam production

- Turn on the pre-accelerator high-Voltage supply

- In the control room increase the Voltage to the value required for the beam, which is typically 120 kV.

- Increase the Ionizer heater current in four-Ampere steps, separated by two-minute intervals while observing the beam current measured on the LE CUP

- Note in the Tandem Log Book, located in the Control Room, the time the source was reactivated and make not of the beam currents.

Turning the Source Down from "Warm Idle" to "Cold Idle" state

Qualified Personnel: All trained accelerator operators

When the use of the negative ion source is no longer required by the experiment, it is desirable to leave the source in a state to prolong the source life time.

- Apply all steps listed for the Temporary Turn-Down above.

- In the control room, turn the source deflectors down and off.

- Turn the inflector magnet supply completely down.

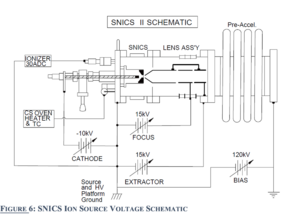

- At the SNICS power supply cage, turn the Lens, Extractor and Cathode H.V. supplies to zero with the control rods extending out of the H.V. cage.

- Reduce the einzel lens voltage to zero by depressing the labeled rocker switch at the H.V. cage control panel.

- Note in the Tandem Log Book, located in the Control Room, the time the source was turned down to the "Cold Idle" mode.

Bringing the Pre-accelerator and SNICS Source to "Secured, Cold" state.

This procedure will only be performed by Brian Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever

- Reaching this state is required before any access to the SNICS Source cage or the SNICS Power Supply cage, for service or repair.

- Bring the source to "Cold Idle" Mode, following the steps described above.

- In the Tandem vault, switch off the pre-accelerator high-Voltage supply, which is located in a rack below the RF Buncher assembly and unplug the power cord labeled "Pre-accelerator high-Voltage supply".

- Lockout the power plug using a lockout device available in the control room cabinet, following the instructions for "SNICS Ion source lockout". and filling an entry in the lockout log book.

- In the SNICS source power cage, verify that the Extraction, Cathode and Lens High-Voltage supplies read "zero" Volts.

- Turn the key switch at the panel to turn off the isolation transformer providing platform power to the H.V. cage. Remove the key from the control panel and place it in the lock box next to the panel. Lock the box and apply a tagout form. Make an entry into the lockout-tagout book.

- Open the cage door in front of the SNICS source.

- A shorting rod is provided, which is attached by cable to the cage door. Hold the shorting rod by its insulated handle, with the tip of the rod touch the source on each side of the endmost ceramic insulator. Repeat touching the parts of the source multiple times, verify that no sparking to the tip occurs, establishing that all parts are at ground potential.

- Hang the shorting rod on the source body, between the air lock VAT valve and the HPS vacuum fitting clamp.

- The source and pre-accelerator are now in "Secured Cold" state, Access to the external source body and the power supply enclosure is now possible.

Bringing the source up from "Cold Secured" state to "Beam" state

These instructions assume the correct cathode is installed and the Ion source vacuum is correct and sufficient to connect to the accelerator

This procedure will only be performed by the qualified personnel B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever

- At the Ion source: Remove the grounding rod from the Ion source and hang it from the cage door in front of the SNICS source

- Close the cage doors in front of the SNICS source.

- Verify that the power supply cage is closed.

- Unlock the lock-box next to the Power supply panel. Obtain the panel-key, insert it into the Power supply front panel and turn it to "on".

- If no source-operation parameters have been recorded or cannot be found set the SNICS Cathode and Extractor supplies to 7.5 KV.

- Open the source exit valve

- Remove the lock on the pre-accelerator high-Voltage supply power cord and plug it in, noting the "unlocked" state in the "lockout tagout" log book located in the control room.

- Turn the pre-accelerator high-Voltage supply on and push the green "High Voltage" button.

- In the Control room: Turn on the pre-accelerator panel and raise the pre-accelerator to the desired Voltage, typically 120 kV.

- Insert the L.E. faraday cup and depress the corresponding push button on the integrator panel. Select the most sensitive scale on the integrator initially and then adjust the scale if and when the beam current pegs the meter.

- Turn the ion source deflectors to zero.

- Adjust the inflector magnet supply to indicate the predicted setting for the negative ion that is to be injected into the Tandem. A table is provided on the inflector control panel.

- If the beam has been run before and the source parameters are known, adjust the SNICS Cathode and Extractor supplies to those values at the High Voltage Cage out in the Tandem Vault. If the Ionizer heater is to be adjusted, do it in 4 ampere steps separated by 4 minutes intervals.

- Beam should now be present on the L.E. cup; if not, adjust the inflector magnet slightly and attempt to find and maximize beam current. The inflector magnet should not be more than 0.15 units off of the predicted setting.

- An iterative approach is used to maximize beam on the L.E. cup. After the magnet is fine tuned, adjust the SNICS Cathode and Extractor supplies in the Tandem Vault to maximize beam current. When satisfied, again adjust the inflector magnet in the Control Room and then the source H.V. supplies again. After this second round of tuning use the source deflectors in the Control Room to increase beam current on the L.E. cup. More rounds of adjustments should be attempted; however, maximum beam transmission through the Tandem does not occur at the same settings as those for maximum L.E. faraday cup beam current. Mostly the source deflectors and the inflector magnet require slight readjustment when tuning through the Tandem.

- Assuming all the focusing and deflector elements are maximized for beam current, one can only adjust the Ionizer heater and the boiler temperature to attain more beam form the source. First, increase the Ionizer one ampere steps until the desired current is reached. The beam is ready for injection.

Should one not have success with tuning the desired beam, reducing the ion source deflectors to 50% of the optimum for a couple of iterations of source voltages and inflector magnet adjustments might be a useful approach. Ultimately, the deflectors should be adjusted to give the maximum beam on target.

Cathode Change Instructions

This procedure will only be performed by the qualified personnel B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever

Bring the source to the "Cold Secured" State, locking out the High-Voltage potentials and power to the source.

- At the source vacuum control panel are two toggle switches that must be placed in the “unprot” position; this is to prevent the isolation transformer from shutting off supplies due to a vacuum excursion in the source. Note the current vacuum indication at the backing line thermocouple controller on the source vacuum panel. Depress the red push button next to the baffle switch while making the change.

- Open the source H.V. cage.

- Hang the shorting rod between the air lock VAT valve and the HPS vacuum fitting clamp.

- Remove the H.V. cathode lead from the stop clamp (aluminum bar) attached to the cathode stainless steel coolant tube.

- Ensure the compression fitting sealing the cathode assembly is only finger tight and then withdraw the assembly slowly and carefully. At 5 3/4” of travel a scribed line on the stainless steel tubing will emerge from the compression fitting. At 1/4” later a second scribed line will emerge indicating that clearance has been afforded the VAT air lock valve and it can be closed. To close the valve rotate the black handle clockwise (up and to the right) until it comes to a stop.

- The green knob on the Nupro valve can now be opened to let the cathode air lock region up to atmospheric pressure.

- Use one hand to withdraw the probe assembly (cooling lines still attached) until it is free from the source. With a glove on the other hand remove (unscrew) the old cathode and replace it with the new one.

- Install the cathode assembly back into the compression fitting; loosen the fitting if necessary to get the probe started and then tighten it finger tight again. Slide the assembly in until the first scribed line is even with the compression fitting.

- A nylon roughing line with a stainless steel tube fitted to its end should be at the source bottom cage grating, ensure its free of debris and insert it into the Nupro valves compression fitting. Snug the fitting on the tube and ensure the valve is still open.

- At the source vacuum control panel, shut the backing valve by putting its toggle switch in the manual close position.

- On the backing line of the source diffusion pump is a right-angle, 1/4” brass valve with a black toggle handle, open this valve to allow the cathode air lock region to be pumped out with the roughing pump. The vacuum can be monitored at the backing line thermocouple controller on the source vacuum panel. When the vacuum has reached the reading previously noted (about 10 microns) close the green handled Nupro valve and then the brass valve on the backing line.

- Vacuum permitting, open the backing line valve with the toggle switch at the source vacuum control panel and place the two toggle switches in step 4 back to the “prot” position. Depress the red push button next to the baffle switch while making the change.

- Remove the nylon roughing line from the Nupro valve and place it back at the bottom cage grating.

- While watching the sputter source penning gauge, open the VAT air lock valve by rotating the black handle counter clockwise (up and to the left) until it comes to a stop. A temporary degradation of the vacuum should be indicated by the penning gauge. If the vacuum does not show signs of recovering in 10 seconds close the air lock valve and determine the source of the gas load. Outgassing of the cathode is not uncommon and is indicated by a vacuum that quickly recovers but not to the level previous to the air lock valve being opened. The vacuum will slowly improve and attain the expected base vacuum of about 1 x 10−7 torr.)

- Carefully slide the cathode assembly into the source until the aluminum stop clamp on the assembly is flush with the compression fitting. There may be an premature stop encountered before the stop clamp is flush with the compression fitting, if so, slightly wiggle the cathode assembly until it is free to be fully installed. Ensure the compression fitting is snug when the installation is complete.

- Reconnect the clear lead for the cathode H.V. supply back to the stop clamp.

- The cathode change is now completed.

- Bring the source back to operation after the source vacuum has recovered to ∼1 x 10−6 torr. The inflector magnet and source supplies can now be tuned for the desired ion and beam current on the L.E. cup.

Description of Typical Cathode Behavior

Most often the material packed into the SNICS cathodes is either a solid or powder. In general, new, unused cathodes are often found to require more time to reach the output level of cathodes that have seen previous use. The nature of the material and how it was stored, particularly if it is a hygroscopic or deliquescent, is of paramount importance to provide reliable negative ion output. Most powdered cathodes are pressed here in the lab and are inherently gassy due to voids in the pressed material. The solid material cathodes are the preferred cathode whenever possible. To reduce damage to the cathodes while they are not in use, it is imperative that the cathodes be wrapped tightly in aluminum foil and placed in a tightly capped bottle that has been back filled with argon.

Solid cathodes when initially inserted into the source, will out-gas in a very short period of time. Beam from the ion source can typically be had in sufficient quantity in a few minutes.

Powder cathodes work best when they are pressed with dry powder and stored in a dry environment. These cathodes will take longer to outgas than their solid counterparts and the ion source extractor and cathode voltages will often suffer stability problems. Previously used cathodes, especially depending on the nature of the material, can sometimes take up to half a day to behave in a stable fashion and produce the desired beam current.

Outgassing a New Ionizer

DO NOT RUN THE IONIZER OVER 290 WATTS This procedure will only be performed by the qualified personnel B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever

- Since the source has just been rebuilt it will need to be pumped on for at least three hours. After this time the vacuum should be in the low 10−6 torr range if there is no leak. Note in the logbook the source vacuum indication previous to outgassing the ionizer filament. If the vacuum has not reached this level in five hours a leak may be present and it will have to be corrected prior to heating the ion source filament.

- The ionizer is typically left with a small current flowing through the ionizer after the rebuild just to ensure continuity. Assuming the vacuum has recovered, increase the ionizer current in three ampere steps every thirty minutes. If the vacuum has degraded to over 5 x 10−6 torr due to a previous current increase, hold off on subsequent increases. When the vacuum has returned to 5 x 10−6 torr or less begin the three ampere increases again.

- When the Ionizer filament power is up to 290 watts for 30 minutes and the vacuum has improved to better than 5 x 10−6, begin looking for beam on the L.E. cup. Go to Sec. 7 for instructions for tuning beam out of the source. Instabilities in the Cathode and Extractor high voltage elements will cause the beam current to be erratic and can be an indication of poor vacuum in the ionizer region. The voltage instability also appears on the high voltage supply meter indications in the source high voltage cage. Patience or a reduction in the filament power level, if beam current requirements allow, should correct this problem. Regardless, reduce the ionizer temperature if possible to prolong its operational lifetime.

RF Ion Source

Theory of Operation

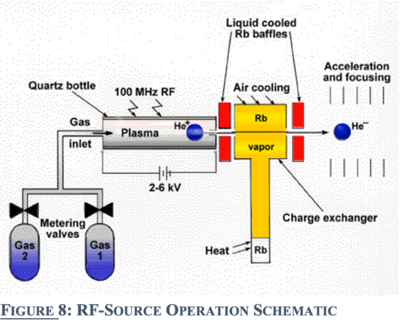

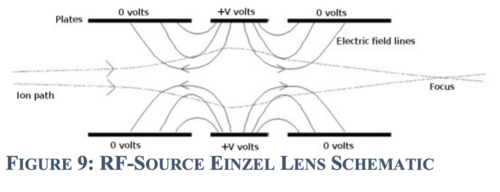

The RF Ion source is almost exclusively used to produce negatively-charged helium beam. Helium is admitted into a quartz tube at a few millitorr, where it is ionized to He+ in an RF discharge. The ions are extracted through a tantalum exit canal by applying a 6 kV positive bias to the probe at the other end of the tube. Most of the probe-bias potential is dropped across a small region near the exit canal and the field lines have the effect of focusing and accelerating the ions through the canal. The ions emerge with an energy close to the probe potential. A large coil around the quartz tube produces a magnetic field which improves the coupling of RF power into the discharge. The He+ ion beam from the exit canal then passes through the Rubidium vapor charge-exchange cell. About 1% of the He+ entering the REC should get converted to He− in the 1s2s2p 4P5 2 metastable state. The negative ion lifetime of approximately 0.5ms is sufficient to reach the Tandem terminal stripper foil. The He- ions are then focused by passing through a gap lens with a potential difference of 7kv. The emerging beam is injected into a pre-accelerator tube.

Ion source operation states

The Helium ion-source has three operation states: "A) Cold, secured": All power sources are removed from the source and locked-out. This state is required for repair or service inside the source body. "B) Warm, secured": All high-voltage potentials are removed from the source, but the RF-power remains active, providing plasma-activation. "C) Beam": All power sources are applied and beam is delivered.

Bring the source from "Beam" to "Cold Secured State" or "Warm Secured State"

This procedure will only be performed by B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

- In the Tandem vault, switch off the pre-accelerator high-Voltage supply, which is located in a rack below the RF Buncher assembly and unplug the power cord.

- Lockout the power plug labeled "Pre-accelerator high-Voltage" using a lockout device available in the control room cabinet, following the instructions for "Ion source lock-out" and filling an entry in the lockout tagout logbook.

- At the back-end on the outside of the source cage, turn the "Gap Lens" power supply to "zero" and the "Probe Power Supply" to zero.

- Open the back-cage door. A grounding-hook connected to a grounded cable is provided.

- Touch the top platform, the aluminum plate below the "Probe Power Supply", then touch the lower platform below the isolator posts to discharge the electrostatic energy.

- Repeat touching these two platforms with the grounding hook several times to verify that no sparks occur when touching the platforms.

- Hang the hook on the corner of the upper platform.

- Switch off the "Gap Lens" and "Probe" Power Supplies.

- Unplug the power "Gap Lens" and "Probe" Power Supplies and secure the with lockout devices, and attach a tag to them.

- Write a corresponding entry in the lockout tagout log book.

- If the source is to be brought into the "Cold Secured State", remove the RF power.

Bringing the Helium Source from "Cold, Secured" to the "Beam" state

This procedure will only be performed by B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

- Remove the lockout device on the "Gap lens" power supplies and plug it into power outlets marked "Vacuum interlocked".

- Remove the lockout tag and return it to the Control room, closing the entry in the log book.

- Set the "Gap Lens" HV supply to positive polarity, leaving it switched off for now.

- Insert the cup and switch it to "positive polarity"

- Turn on the "Probe" power supply, leaving it turned to zero for now.

- Turn on the RF supply power and set the probe magnet to 3-3.5 Amps.

- Open the valve on the helium bottle. Open the helium leak valve until the discharge starts. Close it until the discharge is no longer pink and has become blue. The Penning gauge should only read a few 10−6 torr.

- Remove the grounding-hook from the top platform and secure it at the cage wall, leaving the grounding-hook on the lower platform in place.

- Close the cage doors and turn the Gap Lens supply "on" with the rod from the outside of the cage, raise the Voltage to ~5 kV.

- Using the isolation rod from outside the cage, turn the "Probe" high voltage and set to +5 kV.

- Optimize the positive beam current by varying the gas pressure and the probe magnet settings.

- Once the beam is found to be sufficient (several micro-Amps), turn the Gap-Lens Power supply to zero.

- Open the cage doors and place the grounding hook on the top platform, to verify that electrostatic energy is discharged.

- Set the Oven Heater to ~48 Volts. The Chamber Temperature should rise, approaching ~55 Degrees C after ~20 minutes.

- Switch the Gap-Lens power supply to negative polarity.

- Switch the cup current polarity to "negative".

- Close the cage doors and switch the Gap Lens supply "on" with the control-rod from the outside of the cage.

- Raise the Gap-lens voltage to -5 kV with the control-rod from outside the cage.

- There should be a negative current reading on the cup. Optimize the beam using helium pressure, probe magnet and probe voltages with their respective control-rods.

- Remove the lockout device on the pre-accelerator high-voltage supply power plug remove the corresponding tag and return it to the Control room, closing the entry in the log book.

- Turn the pre-accelerator HV supply on and raise the pre-accelerator voltage to 80kV.

- Optimize the beam current in the accelerator LE cup using the 3-degree magnet current and the Ion source.

RF Discharge Contaminants

Oxygen and other species form negative ions with efficiencies much higher than helium. The admitted helium and desorbed gases from the RF source bottle and boron nitride exit canal insulator can be sources of contaminant beams. For optimum performance it is essential that the RF source bottle assembly be leak tight, that the helium used be greater than 99.99% pure, and that all He tubing and fittings be clean. In addition, it is also important to operate the RF discharge with the helium flowing for 1 or more days prior to the accelerator beam time to allow some of the contaminants to dissipate.