SF6 Gas Handling System

All procedures around the Tandem accelerator gas-handling system will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

Worthington Compressor

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

The Worthington compressor was installed in the early ’70s. It is a two stage oil-less compressor with teflon piston rings and metallic reed valve assemblies. In 1995 the Dresser Rand was the current spare parts supplier (tel.1-800-634-5565). The compressor model no. is 12 1/2 X 5 X 13 HB B-2 and the serial no. is L89186. The compressor is driven by a 125 HP 3-phase motor coupled by belt and pulley. The internal connecting rod and crank do require lubrication and the recommended lubricant is ISO-VG-150; AGMA Grade 4.

The compressor is cooled with well water which is circulated through the water jacket surrounding the compressor cylinders and the heat exchanger. If the well water supply should fail the supply automatically changes over to the city water supply. The discharge from the compressor is sent to the dump well unless a valve change is made to route the water to the storm drain. The two labeled valves in the Gas Handling Room near the compressor need to be set to allow the rerouting. After conditions return to normal and the well supply becomes available again, changes should be made to reroute the well water from dumping down the storm drain; the aforementioned valves will need to be put back in the original state. The switch from city water to well water supply is again automatic.

Emergency Valve Closures

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

If during a gas transfer the compressor should stop, a seal fail or some type of major leak of SF6start, it is important to safeguard the gas inventory. Also, at any time should a SF6 loss due to a failure on the Tandem pressure vessel or the storage tank and any of the directly attached valves occur a transfer of the SF6 inventory is suggested immediately. This, however, should not take precedent over safety as large quantities of SF6 can displace life sustaining air. Depending on where one is in the gas transfer the compressor may or may not be running; the response depends on whether the compressor is running.

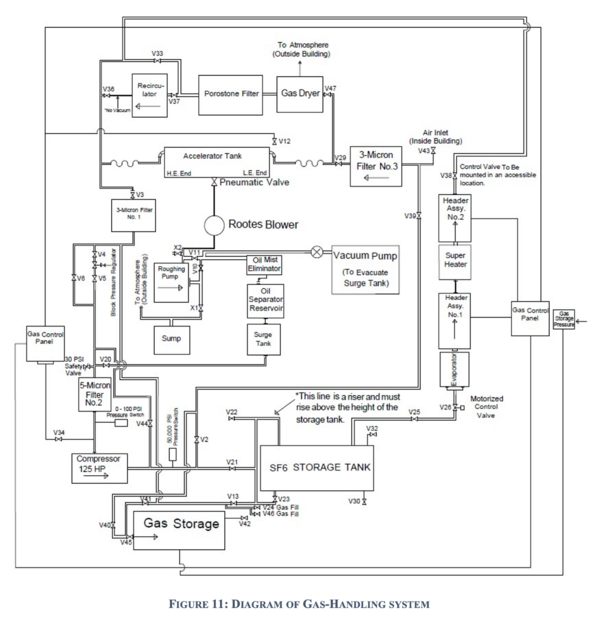

Below are the responses to three sets of circumstances that may confront the operator; some valves may or may not already be closed. The valves affected in the Gas Handling Rm. are shaded red in the preceding room layout (figure 5). After the crisis has passed and the transfer piping schematic (figure 11) is consulted a more sensible arrangement of valves may be preferred.

Compressor is Off: Large Leak Detected

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

| Valve (close in order) | Location |

| LE Tank Valve | Tandem Vault |

| HE Tank Valve | Tandem Vault |

| Valve 45 | Outside atop the bottom white storage tank |

Compressor Has Failed During Gas Transfer: No Leak Detected

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

| Valve (close in order) | Location |

| Valves 5 & 6 | Gas handling room, orange piping, on the W. floor between the back pressure regulator and compressor |

| Valve 20 | Gas handling room, yellow piping, exiting the surge tank |

| Valve 2 | Gas handling room, orange piping on the W. floor between the back pressure regulator and compressor |

| LE Tank Valve | Tandem Vault, south end |

| Pump Pit Pneumatic Valve | Tandem Vault pump pit |

| HE Tank Valve | Tandem Vault, north end |

| Valve 40 | Gas Handling Rm., south wall |

| Valve 41 | Gas Handling Rm., south wall |

Compressor Is On: Large Leak Detected

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

| Valve (close in order) | Location |

| Valves 5 & 6 | Gas handling room, orange piping, on the W. floor between the back pressure regulator and compressor |

| Valve 20 | Gas handling room, yellow piping, exiting the surge tank |

| Turn the compressor off at the control panel | |

| Valve 2 | Gas handling room, orange piping on the W. floor between the back pressure regulator and compressor |

| LE Tank Valve | Tandem Vault, south end |

| Pump Pit Pneumatic Valve | Tandem Vault pump pit |

| HE Tank Valve | Tandem Vault, north end |

| Valve 45 | Outside atop the bottom white storage tank |

Equalizing the SF6 Gas to the Outside Storage Vessel

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

Time: ∼ 25 minutes. Change in Pressure: 80 to 50 lbs/in2.

Ensure these valves are closed before beginning the gas transfer. Refer to the locator map (figure 5) for their approximate location: 38, 39, 43, 47, 35, 36, 4, 6, 13, 46, 40

- In the Control Room, turn off the power to the Terminal Potential Stabilizer panel and withdraw the Corona Probe.

- In the Tandem Vault, open the H.E. Tandem gas valve at the bottom of the North end of the tank. Ensure the tank lights are turned off.

- Open the L.E. Tandem gas ball valve at the bottom of the tank South end.

- Open valve 41, located at the south wall of the gas handling room, to allow the gas to equalize into the Storage Vessel.

- Open valve 29 to collect the gas left in the piping from last gas transfer. The valve will probably be open already. If gas is not heard flowing it may be that valve 3, on the East side of the Tandem is closed, open it.

- In the Control Room, remove the control power key and place it on top of the electronic rack.

- Switch the Gas Pressure Alarm panel to the mute mode.

- When gas is no longer heard flowing through the piping, go to the next step.

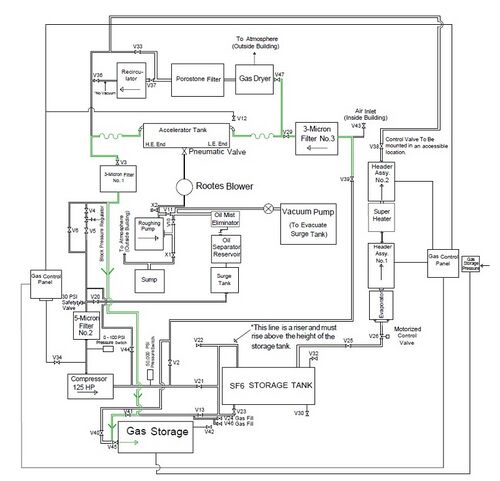

Compressing the SF6 to the Storage Vessel

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

Time: ∼ 90 minutes. Change in Pressure: 50 lbs/in2 to 23” Hg.

- Close the two brass Hygrometer shutoff valves. One is behind the green panel at the H.E. beamline support and the other is on the H.E. Tandem end plate.

- Close valve 41, south wall of Gas Handling Room, to route the gas from the Tandem through the compressor to the Storage Vessel.

- Open valve 40 to allow the gas from the compressor to fill the Storage Vessel.

- Turn on the compressor breaker switch at south-east wall in the Gas Handling Room and ensure cooling water flows through the compressor at the flow gauges located at the north end of the compressor.

- Quickly open valve 2, orange piping on the floor by the back pressure regulator, as soon as the compressor is started. Press the start button on the breaker panel; the compressor will make quite a bit of noise when just starting. The compressor will not start with a positive input pressure. The input pressure to the compressor is indicated by the pressure gauge at the No.2 five micron filter, painted orange and West of the yellow surge tank.

- Open valve 4 and then 5 slowly, the back pressure regulator should ensure the input pressure to the compressor does not go positive. Should a failure occur and the input pressure become positive the compressor will shut down.

- SF6 is fed back into a shaft isolation chamber to prevent air creeping along the shaft into the gas inventory. A pressure gauge located on the compressor, West of the No.2 filter, should indicate a slightly positive pressure ( < 3 lbs/in2). Ensure this is the case.

- After ∼ 30 minutes the back pressure regulator can be bypassed to increase the compressor throughput. Don’t allow the input to the compressor at the 5 micron filter to rise above 8” Hg or the heat exchanger between the two pumping stages to go over 45 lbs/in2 (top gauge on compressor). The bypass is allowed by slightly

- opening valve 6 in steps to maintain the 8” Hg input pressure; eventually the valve will be completely opened.

- Run the compressor until the Tandem’s pressure gauge at the H.E. end registers 23” Hg (approximately -10.8 psig on the Control Room SF6 parameter panel display). The ball valve to the right of the gauge may need to be opened. Proceed to the next section.

Vacuum Pump Boosting for the Compressor

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

- At the H.E. end of the Tandem, connect the Varian 501 gauge controller to the thermocouple. Next to the controller, reset the Rootes Blower run time meter to zero.

- Close the H.E. Tandem gas valve.

- In the Gas Handling Room (figure 5), close valves 4, 5 and 6.

- Open valve 20 slightly and ensure the surge tank pressure begins to drop. The input to the compressor must remain less than atmospheric or the compressor will shut down.

- Entry into the Tandem pit requires strict adherence to procedures for entry into controlled confined space. Fill out an Confined Space Entry Permit form available in the Tandem control room binder.

- The procedure for starting the vacuum pumps follows; they are located below the Tandem in the pit.

- Ensure valve X2, a 1/2” ball valve between the Rootes blower and the Kinney, is closed.

- Open valve X1, located on the pit wall in the Southwest corner, to vent the stagnant air left in the piping and Rootes Blower.

- Start the mechanical pump by depressing the push button located on the panel to the left of the pumps. Hold the button down for at least 3 seconds to ensure the cooling water flow switch latches the pump run contacter. Allow the mechanical pump to run for 30 seconds then continue to the next step.

- There are two switches associated with the Rootes Blower. The upper most switch of the two is a wall type light switch that allows power to the second switch that is a three position switch. The wall light switch must be flipped up to enable the Rootes to come on. Slide the three position switch to the bottom position, manual mode; the Rootes will come on. Allow it to run for 30 seconds and then slide the three position switch to the top, SF6 automatic mode. The Rootes will come on when the Varian 501 controller set point one is reached.

- Wait for the blower shaft to slow and then close valve X1.

- Open V10 which directs the discharge of the vacuum pumps to the compressor input.

- Open the Tandem’s pneumatic valve by turning the key at the control panel and flipping the switch located near the valve on the flexible wire conduit.

- In the Gas Handling Room, open valve 20 the rest of the way, yet maintain a pressure below 8” Hg at the 5 micron filter.

- When the Tandem pressure reaches 4.6 torr, the set point, the thermocouple controller will automatically activate the Rootes blower. If the Tandem pressure is too high the Rootes will trip its circuit breaker and must be reset behind the control panel.

- At ∼ 200 microns begin the shutoff procedure. The Control Room SF6 parameter panel display range of sensitivity will end at approximately -14.2 psig.

Shutoff Procedure

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

- Entry into the Tandem Vault pit requires strict adherence to procedures for entry into controlled confined space. Fill out an Confined Space Entry Permit form available in the Tandem control room binder.

- In the Tandem Vault pit, close the Tandem pneumatic valve in the vault pit. Use both the toggle switch and the key.

- Turn off the Rootes Blower wall light switch and slide the 3-position switch to the manual mode, the bottom position. Allow the blower to slow.

- Close V10 which isolates the input to the compressor.

- Open the l/2” yellow ball valve labeled X2 between the Rootes blower and the Kinney pump.

- Turn off the mechanical pump by depressing the stop button.

- Close valve X2 when air no longer flows.

- In the Gas Handling Room (figure 5), close V20 yellow piping.

- Quickly close V2 orange piping, after the compressor is turned off by depressing the push button. Turn the breaker to off after the valve is closed.

- Close V40, south wall in the Gas Handling Room.

- Disconnect the thermocouple controller from the gauge head at H.E. end of the Tandem.

Venting the Tandem to Air

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

Time: ∼ 30 minutes + 2 hours. Change in Pressure: 150 millitorr to 1 atmosphere.

- Turn the Tandem door ports to the open position. The vacuum will keep the ports sealed shut.

- Partially open valve 43, red piping in gas handling room (figure 5). As the flow is heard slowing, open valve 43 more. Continue until completely open.

- After the door ports are open, indicating that atmospheric pressure is reached, close valve 43.

- Open the LE and HE tank doors on the front side of the tank completely.

- Place the fan in the Tandem L.E. port and turn on so that air is pulled out through the L.E. port.

- Leave the air circulation on for at least two hours before entering the tank.

- Assess the air quality with a portable air quality monitor

- Turn on tank lights. The Tandem is ready for floor boards and/or working inside.

- Access to the Tandem tank requires strict adherence to "Confined Space" procedures, fill out a confined space entry permit available in the corresponding control room binder.

Removing Air from the Tandem

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

Time: ∼ 14 hours (overnight). Change in Pressure: 1 atmosphere to 25 millitorr.

- Remove all items brought into the Tandem, wipe the terminal off with alcohol and paper towels, remove the floor boards and sweep the bottom of the tank clean. Ensure no debris is left on the Tandem pneumatic valve flapper surface inside the tank; use the ShopVac vacuum cleaner. Turn the Tandem tank lights off.

- Shut the Tandem port doors and turn them partially closed. It will be difficult to completely close them until a vacuum is established. Make an attempt to close them at 14” Hg; typically, the lower the vacuum reached the easier it is to turn close the port doors.

- Ensure that valves 2 and 43 in the Gas Handling Room and 10 and 11 in the Tandem pump pit are closed (See figure 5).

- Ensure that valve X2, a 1/2” ball valve between the Rootes blower and the Kinney pump, is closed.

- Open valve X1 to allow pumped air to exit the building.

- Start the mechanical pump by depressing the push button located on the panel to the left of the pumps. Hold the button down for at least 3 seconds to ensure the cooling water flow switch latches the pump run contacter.

- There are two switches associated with the Rootes Blower. The upper most switch of the two is a wall type light switch that allows power to the second switch that is a three position switch. The wall light switch must be flipped up to enable the Rootes to come on. Slide the three position switch to the middle position, air automatic mode. The Rootes will come on when the Varian 501 controller set point two is reached.

- Open the Tandem pneumatic valve by turning the key at the control panel and flipping the switch located near the valve on the flexible wire conduit.

- Connect the Thermocouple controller to the gauge head at the H.E. end of the Tandem.

- Allow the Tandem to be pumped on over night to remove absorbed gases and water vapor.

- In the morning the Tandem vacuum should be at ∼ 25 millitorr. Close the pneumatic valve with the key and toggle switch. Turn off the Rootes Blower wall light switch and return the three position switch to the manual mode, slide to the

- bottom position. Allow the blower to slow.

- Close X1 which allows the pumps to exhaust outside the building.

- Open the l/2” yellow ball valve labeled X2 between the Rootes blower and the Kinney pump.

- Turn off the mechanical pump by depressing the stop button.

- Close valve X2 when air no longer flows.

- Check and top off if necessary the Rootes blower and Kinney pump oil.

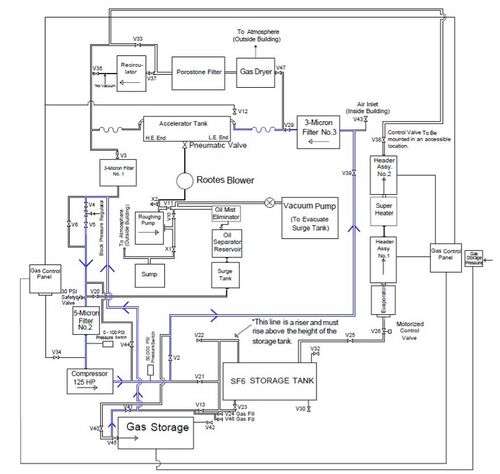

Equalizing SF6 into the Tandem

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

Time: ∼ 60 min. Change in Pressure: 25 millitorr to 50 lbs/in2.

- Close the ball valve before the +30 psi -30” Hg gauge at the H.E. end of the Tandem.

- Disconnect the Thermocouple controller lead from the gauge head.

- Ensure valve 41, in the Gas Handling Room (figure 5) behind the yellow paint cabinet, is closed.

- Open valve 39, red piping to the left of the grey drier/desiccant tanks.

- Open valve 40 (next to 41) partially, especially on cold mornings to prevent thermal shock to the accelerator column. As the flow rate is heard slowing, rotate the ball valve open more.

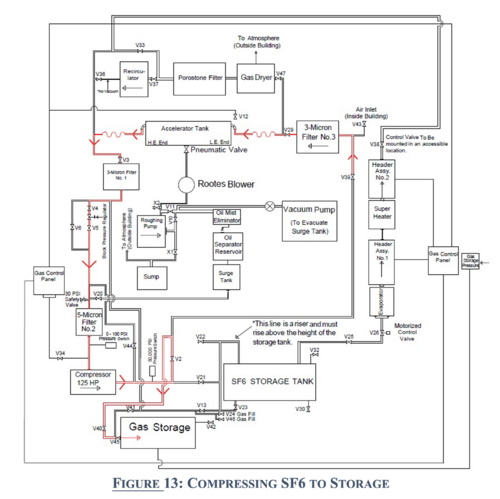

Compressing SF6 into the Tandem

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

∼ 4 hours, 50 to 90 lbs/in2.

- Close valve 40, south wall of Gas Handling Room (figure 5).

- Open valve 41 to route the gas from the Storage Vessel though the compressor to the Tandem.

- Turn on the compressor breaker switch at south-east wall in the Gas Handling Room and ensure cooling water flows through the compressor at the flow gauges located at the north end of the compressor

- Quickly open valve 2, orange piping on the floor by the back pressure regulator, as soon as the compressor is started. Press the start button on the breaker panel; the compressor will make quite a bit of noise when first starting. The compressor will not start with a positive input pressure. The input pressure to the compressor is indicated by the pressure gauge at the No.2 five micron filter, painted orange and West of the yellow surge tank.

- Open valve 4 and then 5 slowly to ensure the input pressure to the compressor does not go positive; this will result in the shut down of the compressor.

- SF6 is fed back into a shaft isolation chamber to prevent air creeping along the shaft into the gas inventory. A pressure gauge located on the compressor, West of the No.2 filter, should indicate a slightly positive pressure (<3 lbs/in2). Ensure this is the case.

- After ∼ 30 minutes the back pressure regulator can be bypassed to increase the compressors throughput capacity. Do not allow the input to the compressor at the 5 micron filter to rise above 8” Hg or the heat exchanger between the two pumping stages to go over 45 lbs/in2 (top gauge on compressor). The bypass is allowed by

- slightly opening valve 6 in steps to maintain the 8” Hg input pressure; eventually the valve will be completely opened.

- Run the compressor until the input pressure at the 5 micron filter registers ∼ 27” Hg

- Close valve 41.

- Close valves 4, 5 and 6.

- Stop the compressor and quickly close valve 2. Ensure the breaker is turned off after the valve is closed.

- Close valve 39.

- Close the L.E. Tandem gas valve.

- Open the two brass Hygrometer shutoff valves. One is attached to the back of the green panel at the beamline support and the other to the H.E. Tandem end plate.

- Turn the Gas Pressure Alarm panel back to “aural” in the Control Room. The gas transfer is complete.

Adding SF6 to the Inventory from Cylinder

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

SF6 is usually delivered in cylinders that come in two sizes: A and B. The cylinders are filled with liquid and their pressure will be the SF6 vapor pressure for the cylinder temperature. Due to the latent heat of vaporization, it will be necessary to add heat to the cylinder as the liquid changes to the gaseous phase and fills the Tandem. A typical pressure encountered would be ∼ 270 lbs/in2. At this vapor pressure the majority of the cylinder contents can be added directly to the tandem. When all the liquid has evaporated and the cylinder pressure matches the Tandem’s additional effort is necessary to empty the remaining cylinder contents. The last bit of gas can be sent to storage for recovery at the next gas transfer or the SF6 compressor can be used to add directly to the Tandem inventory.\

Adding SF6 directly to the Tandem From Cylinders

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

- Remove the cylinder caps and the plastic thread protector that often accompanies the valve. Attach the SF6 cylinders to the flexible lines at the fill manifold in the Gas Handling Room (figure 5); the cylinder threads are left handed. Attach the cylinder heaters to the bottom of the cylinders. If plastic mesh surrounds the bottle, roll it back on itself to ensure it does not melt.

- Open the cylinder and fill line valves. Open the valve isolating the pressure gauge at the end of the fill manifold.

- Close valve 45 located outside on top of the storage tank. Inside the Gas Handling Room ensure they’re closed or close valves 13, 2, 43, 47, 4 and 6. In the Tandem Vault ensure valve 3, on the East side of the Tandem, is closed.

- In the Tandem Vault open the L.E. valve. In the gas handling room open valves 41, 40, 39, 29 and 46. The cylinders should now be emptying and will begin cooling down.

- Turn on the heaters at the breaker panel around the corner from the fill station and leave them on until the cylinders either feel warm approximately 12” up from the heaters or SF6 no longer flows from the cylinders.

- When the cylinders’ pressure has equalized with the tandem pressure, close valve 40. Continue to the next step to remove the remaining SF6.

Removing the SF6 remaining in the cylinders at Tandem pressure

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

These two procedures assume the valves are still in the state they were left in when adding the cylinder SF6 to the Tandem. Part A describes the procedure for transferring the residual cylinder gas with the compressor to the Tandem. Part B describes the procedure for transferring the residual cylinder gas to storage for addition to the gas inventory at the next gas transfer.

Part A, to the Tandem:

- Turn on the compressor breaker switch at south-east wall in the Gas Handling Room (figure 5) and ensure cooling water flows through the compressor at the flow gauges located at the north end of the compressor.

- Quickly open valve 2, orange piping on the floor by the back pressure regulator, as soon as the compressor is started. Press the start button on the breaker panel; the compressor will make quite a bit of noise when just starting. The compressor will not start with a positive input pressure. The input pressure to the compressor is indicated by the pressure gauge at the No.2 five micron filter, painted orange and West of the yellow surge tank.

- Open valves 4 and 5 while keeping the heat exchanger below 50 lb/in2. Valve 6, the regulator bypass, can be utilized yet keep the input to the compressor below atmospheric.

- Pump on the cylinders until the compressor is at 28” Hg. Often there is a check valve installed on the cylinders that prevent a vacuum being drawn which may cause contamination of the cylinder, close valve 46 to check the cylinder pressure. Ensure the cylinders are left with little pressure by cycling valve 46 until satisfied.

- Quickly close valve 2 orange piping, after the compressor is turned off by depressing the push button. Turn the breaker to off after the valve is closed.

- In the Tandem Vault close the L.E. valve and open valve 3. In the Gas Handling Room close valves 4,5, 6, 41, 39, 46, fill line valves, cylinder valves and gauge valve.

- Open valve 45 on top of the outside storage tank.

- Return the empty cylinders to outside storage for return. Use the chains provided on the West side of the Gas Handling Room loading dock to secure the cylinders.

Part B, To storage:

- In the Tandem Vault close the L.E. valve. In the gas handling room close valves 41 and 39.

- Open valve 45 on top of the storage tank outside.

- Back in the Gas Handling Room, open valve 41 to allow the SF6 to flow to the storage tank. Often there is a check valve installed on the cylinders that prevents a vacuum being drawn which may cause contamination of the cylinder, close valve 46 to check the cylinder pressure. Ensure the cylinders are left with little pressure by cycling valve 46 until satisfied with the cylinder residual.

- After the cylinders are emptied close the individual cylinder and manifold valves. Close valve 41.

- In the Tandem Vault open valve 3.

- Return the empty cylinders to outside storage for return. Use the chains provided on the West side of the Gas Handling Room loading dock to secure the cylinders. A call to the supplier of the SF6 will hasten the cylinder collection.

SF6 Gas Drying

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

The three major components of the gas drying system are the blower, desiccant tanks and hygrometer. SF6 from the accelerator is removed at the L.E. valve passed through the dryer circuit and then returned through the H.E. valve via the blower. The desiccant beds will remove water from the gas as it is continuously cycled until a sufficiently low dew point or water vapor content is reached, ∼ 10 ppm. The desiccant in the tanks does, however, adsorb a finite amount of water and will require reactivating when it has become saturated. The desiccant is reactivated by passing hot air through the tank evaporating the water that was removed from the SF6.

Reactivating the Gas Dryer

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

- Ensure valves 35, 37 and 47 are closed.

- Inspect the pressure gauges atop the silver/grey desiccant tanks. If they are pressurized slowly open valve X-3 to release the pressure.

- After the tank pressure is released, open valve X-4 and turn on the power at the red electronics box to the north of the desiccant tanks. A blower should come on along with the heater elements; the red light atop the electronics box should be illuminated.

- Allow the reactivation cycle to continue; it will automatically shut off when the desiccant tank temperature reaches the thermostat set point, ∼ 3 hours.

- Close the two valves X -3 and -4, and turn off the switch at the electronics box. Allow the desiccant tanks to cool to room temperature before attempting to dry the SF6.

Recirculating the Gas

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

This procedure assumes the Tandem has been secured in the normal fashion after being gassed-up and the dryer has been reactivated.

- Ensure valves 35 (blue piping Gas Handling Room, figure 5), 29 (red piping Gas Handling Room), 3 (orange piping east side of Tandem), X-3 and X-4 (gray piping gas handling room) are CLOSED.

- Open valves 36, 37, 47 (blue piping gas handling room), the L.E. Tandem valve and H.E. Tandem valve.

- The power switch for the blower used to recirculate the SF6 through the desiccant tanks is located at the fuse box to the left of the entrance to the Tandem Vault

- L.E. end labeled Recirculator. Three push buttons are located at the bottom of box, also, a grey extension cord should be hanging from the bottom, plug the cord into one of the outlets immediately to the right. Depress the start button to turn on the blower in the blue tank in the north east corner of the Gas Handling Room.

- Allow the gas to recirculate through the dryer circuit until the hygrometer indicates a dew point or water vapor concentration that is acceptable (below -50◦F)

- Turn off the blower and close valves 36, 37, 47, the L.E. Tandem valve and H.E. Tandem valve.

- Ensure that valves 3 and 29 are left open.

SF6 Leak Checking Gun

These procedures will only be performed by qualified personnel: B. Schmidt, Dr. L. Baby or Dr. I. Wiedenhoever.

When ever a SF6 leak is suspected, or when making routine checks after gas transfers the SF6 leak detector or leak checking gun can be used to localize small, inaudible leaks as small as 0.2 cc/sec. Normally the gun is kept in the gray Tandem Cabinet in the NW corner of the control room. Detailed instructions concerning the gun are included in the black carrying case. A general description for setting the detector up follow and are included in the carrying case.

- Ensure there is at least 150 lbs. of argon pressure in the cylinder. Open the cylinder valve to check this.

- On the gun, turn the selector switch to the check volts position and squeeze the guns trigger; the meter should indicate between 60-80 divisions unless the batteries need replacing.

- The Detector will require a purge period of five minutes or so. Press the check detector button while simultaneously squeezing the trigger; the meter should indicate 0 before the purge and 40 or more divisions afterwards. It does not some maintenance of the gun is in order.

- Turn the selector switch to the appropriate sensitivity and adjust the zero. Normally I adjust it to zero while at the highest sensitivity in the Control Room. The zero setting will be altered some as the detector cell cleans up.

- Check the pressure vessel for leaks by bringing the gun barrel or tip into close proximity to areas suspected of leaking SF6.

- Ensure the cylinder is turned off before putting the leak checking gun in the carrying case and back into the gray cabinet.

Contact

- Brian Schmidt, Senior Research Associate email bschmidt@fsu.edu, Tel. (850)644123 (work), (850) 4424338 (home)

- Dr. Lagy T. Baby, Research Faculty III email lbaby@fsu.edu, Tel. (850)9800057 (cell)

- Dr. I Wiedenhoever, Professor of Physics email iwiedenhoever@fsu.edu, Tel.(850)7285912 (cell)